Precor EFX 800

The EFX 800 is a groundbreaking, feature rich elliptical designed for the rigors of daily use in a commercial gym. The goals of the product were to make it easier than ever to service, incorporate a more natural converging foot path and lay the ground work for efficient assembly and production methods across the commercial line.

A Revolutionary Experience

The elliptical trainer is a staple in many gyms around the world, providing low impact, high intensity exercise that has helped transform the lives of millions of people. Precor was the original inventor of this exercise motion and has since evolved the product to one of the most valuable pieces of equipment a fitness club can own. Four generations of product and nearly twenty years after its inception, Precor revisited the Elliptical Fitness Cross Trainer (EFX) to drive it even closer to perfection.

Exploration Towards Definition

Why do we need to make a new elliptical? In the fitness industry we typically work on five to seven year product cycles - at the inception of this project we were nearing our eighth year without a total product refresh. To stay competitive in the industry, we audit every facet of the product possible areas of improvements and differentiation.

Leading up to development, the industrial design team becomes heavily integrated with engineering and product management to create a thorough understanding of where we can improve the existing product while looking towards our key customers for insights.

Market Requirements

Utilizing nearly a years worth of user data, field research, customer interviews and product testing, the industrial design, engineering and marketing teams reduced the action item list to these overarching requirements for the next elliptical.

Cleanable surfaces

Approachable to new users

Comfortable touch points

Highlight innovative motion

Integrated storage solutions

Appearance of mechanical simplicity

Clear familial connection

Implied visual motion

Development Begins

In the early phase of development, we outline where we can improve our product and compare that against current trends and competitive companies while striving to retain the underlying DNA that makes our products 'Precor' products.

Opportunity Areas

By highlighting the major pain points of the existing elliptical, possible ways to improve the product to fit the specifications of the market requirement document became more clear.

-

Form opportunities exist in designing refined, elegant surfaces that will prevent debris ingress and contribute to a less mechanically exposed look.

-

Concept exploration should pursue designs that will portray a sense of refinement at mechanical attachment points. Opportunities should include shrouding mechanisms/fasteners, creating integrated joints, and combining parts to establish a more unified appearance.

-

Carrying on with success found in the one piece elastomer and rodeo grips of the AMT, designs should continue to evolve touch points to be clean, elegant and tactile. LED blue should be explored to call attention to key design elements for functional zones.

Surface Elements

Along with color breakup and proportions, focusing on consistent types of surface breaks will help align the family of Precor cardio products.

Sketch Exploration

Sketching exercises ranged from full gestural concepts down to the individual componentry. These sketches were then used to help the engineering team design an internal structure. The industrial design and engineering teams worked concurrently to design an underlying structure that fits the needs of both groups, allowing the design to move forward confidently. Concepts were grouped into common themes, then scrutinized by the industrial design and engineering teams before choosing a direction to develop further.

Defining Spatial Volume

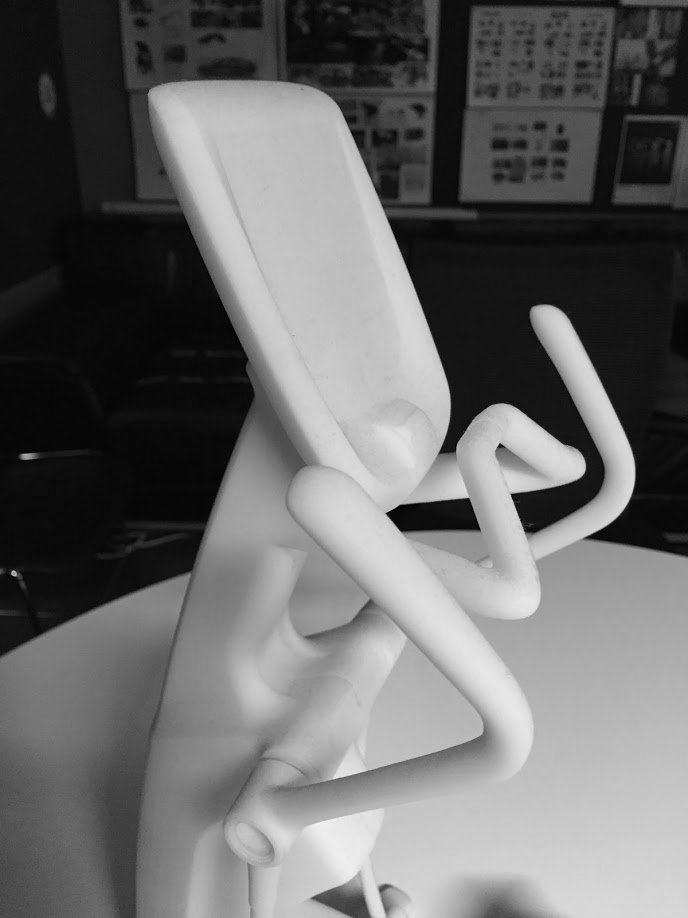

After choosing a direction, rough volumes were blocked out in Solidworks and 3D printed as a scale model to give us a better understanding of proportion, spacial presence and potential part breakup.

Defining Keep-out Clearances

Before building a full scale prototype, we place volumes in real space to work out positioning of key features like grips and water bottle holders to make sure we stay clear of moving parts and bodies.

Full Scale Models

We built up four full scale prototypes throughout this phase of the project, each one acting as a Mr. Potato head for new components as we designed them. Each iteration brought us closer to the final product as parts were evaluated through a cost and manufacturing constraint lens.

Working Prototypes

A combination of real components, fabricated steel, 3D printed parts and a couple cans of bondo helped us create a full scale working elliptical for multiple teams to evaluate. Purposely keeping the model a neutral gray aided us in the review process as it signified the product was still in a development phase.

After soliciting feedback, we spent another couple weeks implementing changes, removing and adding parts, and giving the product a fresh paint job before restarting the review cycle. At this point, most of the contained components such as pedals and link covers are ready to be sent off for tooling, though the mechanical engineering team will still be disassembling and reassembling the larger parts while they finely tune the interior features.

Final Product

Based on research with customers, operators, servicers and our own observations, the features embedded in the final product have helped to make this the best and most reliable and feature rich elliptical we have ever sold.

Welcome to the family

To maintain a consistent language, we focused on retaining similar color breakups and volumes, common tubes and a forward directing stance. Retaining common elements within the cardio family are paramount in creating a strong and recognizable brand image within the club and on the sales floor.

Converging CrossRamp®

One of the most visible changes to the EFX design: the Converging CrossRamp®. To achieve the most natural feel, motion paths were mapped from runners and walkers and were transposed into CAD data that was used to engineer the shape of the ramp. The resulting shape was a converging path that curved in three axes to properly match the gait of the exerciser, requiring a departure from the conventional extruded aluminum ramp. Borrowing technology from automotive manufacturing, the new ramp would be stamped from thick stainless steel to give it both rigidity and corrosion resistance while allowing the path to form a compound curve.